Understanding and Applying Pump Affinity Laws for Efficient Pump Performance

Overview

The Pump Affinity Laws, also known simply as the Affinity Laws, are a set of principles that describe how the performance of centrifugal pumps changes in response to variations in speed or impeller diameter. These laws are essential for understanding and predicting pump behavior under different operating conditions, allowing engineers to optimize pump performance efficiently.

What are the Pump Affinity Laws?

The Affinity Laws explain how key pump characteristics—such as flow rate, head, and power—change when the pump speed or impeller diameter is altered. These laws are based on mathematical relationships and help engineers make informed decisions about pump design and operation.

Key Affinity Law Equations

The Affinity Laws provide three core relationships:

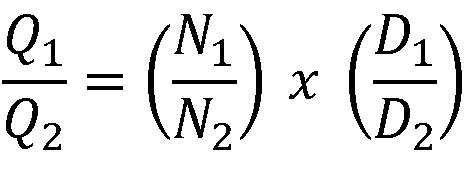

- Flow Rate (Q) varies directly with the speed (N) and impeller diameter (D):

(Eqn .1)

This shows that if you increase the pump speed or the impeller diameter, the flow rate will increase proportionally.

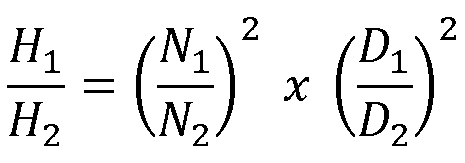

- Head (H or ΔP) varies with the square of the speed and diameter:

(Eqn .2)

This relationship shows that increasing the speed or diameter will lead to a squared increase in the head (or pressure difference) the pump can generate.

- Brake Horsepower (BHP) varies with the cube of the speed and diameter:

(Eqn .3)

Power consumption is highly sensitive to changes in speed and impeller diameter, as it increases by the cube of these parameters. Small increases in speed or diameter can lead to significant increases in energy usage.

Practical Applications of the Affinity Laws

Understanding the Affinity Laws allows engineers to predict how a pump will perform at different speeds or with different impeller sizes. This is particularly useful when selecting or modifying a pump to meet specific operating conditions. By using these laws, engineers can estimate changes in flow, head, and power without needing to conduct extensive testing.

However, it’s important to remember that these laws are approximations. They are most accurate for small changes in speed or impeller diameter. For larger changes, it's essential to consult the pump manufacturer to verify the predicted performance and apply any necessary correction factors.

Variable Speed Drives and Pump Optimization

One of the most impactful applications of the Affinity Laws is in energy conservation through the use of Variable Speed Drives (VSDs). By adjusting the pump speed, VSDs allow pumps to operate more efficiently and reduce energy consumption, especially in systems where full-speed operation is rarely needed.

In some cases, the Affinity Laws can reveal opportunities for downsizing pumps. If a pump is consistently running below full capacity, reducing its size or optimizing its operation with a VSD can lead to significant cost savings in both energy and maintenance.

Conclusion

The Pump Affinity Laws are a fundamental tool for engineers looking to optimize the performance of centrifugal pumps. By understanding how speed and impeller diameter impact flow rate, head, and power consumption, engineers can make data-driven decisions to enhance pump efficiency and reduce energy costs.

Whether you're selecting a new pump, adjusting an existing one, or considering energy-saving retrofits like variable speed drives, the Affinity Laws provide a reliable framework for predicting and improving pump performance. In today’s energy-conscious world, applying these principles can lead to significant savings and more sustainable pump operations.

For a deeper dive on pumps, check out the Pump Sizing & Modeling Piping Systems For Liquids Course

Receive Free Discounts!

Join our mailing list to receive the latest engineering blogs, tools, resources and discounts on courses.

Don't worry, your information will not be shared.