What is NPSH (Net Positive Suction Head)?

This guide outlines key concepts related to NPSH (Net Positive Suction Head), including how to calculate NPSHa and NPSHr, how to troubleshoot cavitation issues, and how to apply proper safety margins when selecting pumps.

- NPSHa

- NPSHr

- Solving NPSH issues

- NPSHa/NPSHr ratios to select

What is NPSH (Net Positive Suction Head)?

When dealing with pumps, NPSH, or Net Positive Suction Head, is a key factor engineers use to ensure safe and efficient pump operation. Understanding NPSH is crucial to preventing pump damage, such as cavitation, which can significantly impact performance.

NPSH, also referred to as net positive suction head, is a calculation used by engineers and pump manufacturers to ensure the safety operation of a pump.

Types of NPSH: NPSHa and NPSHr

There are two types of NPSH:

- NPSHa (Net Positive Suction Head Available): A system property.

- NPSHr (Net Positive Suction Head Required): A pump-specific property provided by the manufacturer.

NPSHa (Available)

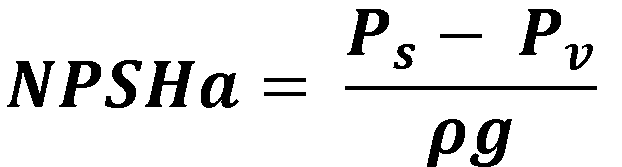

NPSHa is a property of the system, calculated using the following equation:

(Eqn.1)

Where:

NPSHa: Available net positive suction head (m).

Ps: Pressure at the inlet suction of the pump suction (Pa).

Pv: Vapor pressure of the liquid at the operating temperature (Pa).

ρ: Density of the liquid (kg/m³).

g: gravitational constant (9.81 (m/s2).

This NPSHa equation calculates the difference between the pressure of the fluid at the suction side of the pump minus the fluid vapor pressure, expressed in meters (NOT Pressure!).

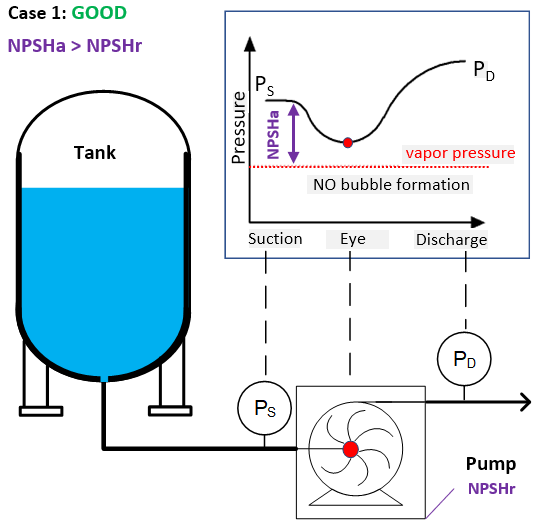

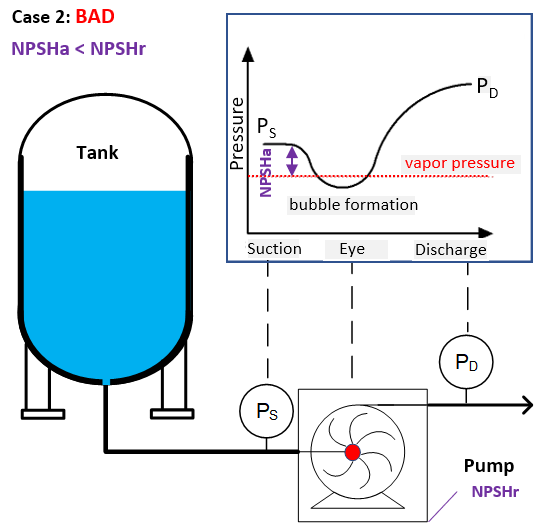

The NPSHa equation shows how much higher the pressure at the pump inlet is compared to the fluid’s vapor pressure. When fluid enters the pump, the pressure naturally drops as it moves toward the impeller. If the suction pressure is too low or the vapor pressure is too high (resulting in low NPSHa), cavitation can occur. This is when the fluid turns into vapor inside the pump, forming bubbles. As these bubbles collapse back into liquid due to pressure changes, they can cause significant damage to the pump. Figures 1 and 2 below illustrate how cavitation occurs and how it affects pump performance.

Figure 1 (left): Shows the case where no cavitation occurs.

Figure 2 (right): Shows the case where cavitation occurs.

Preventing Cavitation

To avoid cavitation, NPSHa must always exceed NPSHr at all flow rates:

NPSHa>NPSHr

Cavitation can damage pumps, so maintaining a proper safety margin between NPSHa and NPSHr is crucial.

Calculating NPSHa: A Practical Example

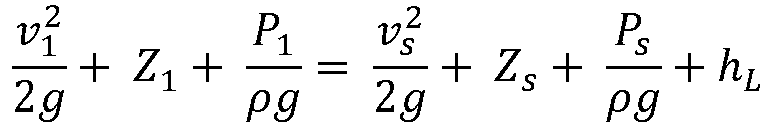

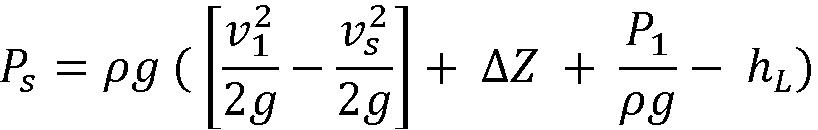

To calculate NPSHa, use an energy balance around the suction side of the pump. For a system with a reservoir tank, the suction pressure can be determined as:

(Eqn.2)

Simplifying this equation to solve for suction pressure:

(Eqn.3)

Where:

- V1 and Vs are the fluid velocities at point 1 and the pump’s suction side, respectively.

- P1 and Ps represent the pressures at point 1 and the suction side of the pump, respectively.

- ΔZ is the elevation difference between Z1 (the liquid surface at point 1) and Zs (the pump inlet).

- hL refers to the friction loss caused by the pipe and fittings connecting the tank to the pump."

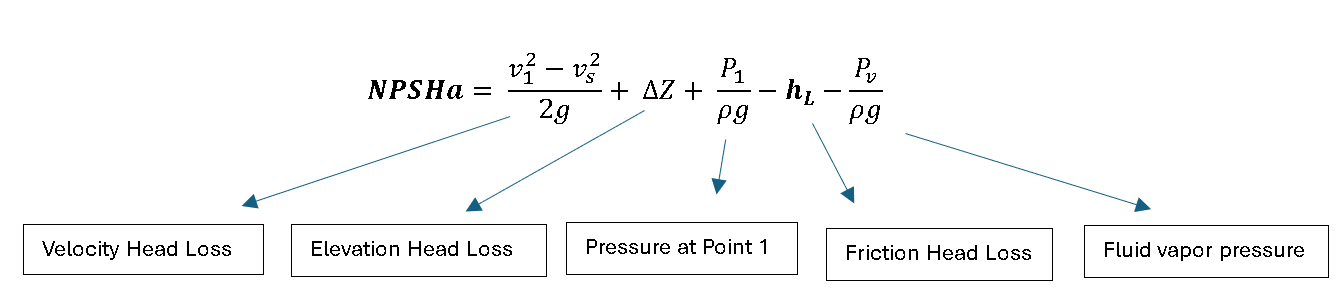

By substituting this back into the NPSHa equation:

(Eqn.4)

As you can see, the NPSHa of your system is directly influenced by several factors, including velocity head loss, elevation head, friction head loss, reservoir tank pressure (at point 1), and the fluid’s vapor pressure, which changes with temperature.

Depending on the application, some simplifications can be made. For example, if the reservoir tank diameter is large, fluid velocity may be so small that it becomes negligible. However, it’s important to understand and use the full NPSHa equation (Eqn. 4) rather than relying on shortcut equations that might not suit your specific setup.

If you're experiencing NPSH issues like pump cavitation, refer to the section below for troubleshooting tips

NPSHr (Required)

NPSHr is a pump-specific property, provided by the manufacturer. When selecting a pump, ensure that the NPSHa of your system exceeds the NPSHr at all flow rates to avoid cavitation.

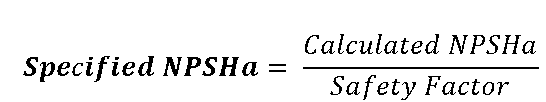

NPSH Safety Margin

NPSHr is a property of the pump, which the pump manufacturer provides along with the pump curve and other pump performance characteristics. If you fill a pump datasheet correctly where you identify the NPSHa of your system, the manufacturer will provide you with pump options that have a NPSHr which would satisfy your operation. However, It is the duty of the engineer to make sure that the NPSHa is greater than the NPSHr before purchasing the pump. See the table below which outlines good practices on the ratios for NPSHa/NPSHr to maintain.

Understanding NPSH Margin: How to Prevent Pump Cavitation

The NPSH margin is the difference between NPSHa (Net Positive Suction Head available) and NPSHr (Net Positive Suction Head required). To prevent cavitation, which can damage pump performance, it's critical that the NPSHa is always greater than the NPSHr.

For added safety, the Hydraulic Institute recommends maintaining an NPSH margin of 3 to 5 feet for centrifugal pumps and 7 to 10 feet for reciprocating pumps. This helps reduce the risk of cavitation and improves the reliability of your pumping system.

Another method to ensure a safe NPSH margin is by using a safety factor. This involves dividing your calculated NPSHa by a safety factor, effectively specifying a lower NPSHa to the supplier than what was actually calculated for your system:

(Eqn.5)

Typical Safety factors

- = existing system

1.10 = new services that have stable and well-controlled suction conditions

1.25 = new or old services that tend to have rapid, frequent, or severe fluctuations in suction conditions, such as boiler feed water pump.

By applying either of these two methods—maintaining an adequate NPSH margin or using a safety factor—you can ensure your pump is protected from cavitation, improving performance and longevity.

How to Solve NPSH Issues: Effective Solutions for Increasing NPSHa

If you're dealing with NPSH problems that could lead to cavitation, here are some practical solutions to increase NPSHa (Net Positive Suction Head available) in your system:

- Increase Elevation Head:

Raise the liquid level in the tank or lower the pump to increase the elevation difference, boosting NPSHa. - Increase Reservoir Pressure:

Pressurize the tank by introducing compressed air or nitrogen to increase the available NPSHa. - Lower Operating Temperature:

Reducing the fluid temperature lowers its vapor pressure, effectively increasing the available NPSHa. - Decrease Friction Loss:

Increase the suction pipe diameter to reduce friction losses in the line, helping to maintain a higher NPSHa. - Add a Booster Pump:

Install a booster pump in the suction line to raise the pressure and improve NPSHa.

Alternatively, you can reduce the NPSHr (Net Positive Suction Head required) of the pump by:

- Increase Pump Impeller Diameter:

A larger impeller reduces the pump’s NPSHr, making it easier for the available NPSHa to meet or exceed the required threshold.

For a deeper dive on pumps, check out the Pump Sizing & Modeling Piping Systems For Liquids Course

Receive Free Discounts!

Join our mailing list to receive the latest engineering blogs, tools, resources and discounts on courses.

Don't worry, your information will not be shared.